As an Architect, I have witnessed firsthand the challenges project teams face in ensuring that construction projects are executed according to plan. I always considered it remarkable that only 5–10% of a construction project is typically checked against the plan, leaving project leaders relying on outdated or low-resolution information to make critical decisions, which all lead to budget and schedule overruns due to repeated errors and increased uncertainty.

So why does this happen? Why is only 5–10% of a construction project checked against the plan?

One of the reasons why only a tiny portion of a construction project is checked against the plan is that it is simply not humanly possible to check everything. Large complex projects involve the installation of millions of elements, so checking everything regularly is too time or cost prohibitive to be practical it would require massive teams of experienced industry professionals to review and check work. And surfacing mistakes is like finding a needle in a haystack.

We estimated that a single project validating 1 week of construction generated 2 months of gruelling flat-out manual work to document, validate and track everything. That’s not even taking into account that even the most diligent industry professionals are prone to errors.

This information gap between design and build leaves projects open to significant risk.

The consequence of not finding the needle in the haystack

Typically when there are deviations from the plan, these issues surfaced and it takes months before the management team is made aware, reducing the time available to mitigate issues and coordinate solutions. Leading to 2nd or 3rd order issues creeping in, producing a larger issue.

If left undiscovered, the consequences manifest as rework where work must be torn down and done again, or costly re-design of the building must be undertaken. This inevitably leads to schedule delays and more project risk.

Real-world impact

The consequences are all around us. Delays and cost overruns have plagued the construction of the new Berlin-Brandenburg Airport in Germany. Initially scheduled to open in 2012, but construction errors and low-resolution quality control have caused numerous delays. The latest estimates suggest that the project, which was initially budgeted at €2.4 billion, could end up costing as much as €7 billion.

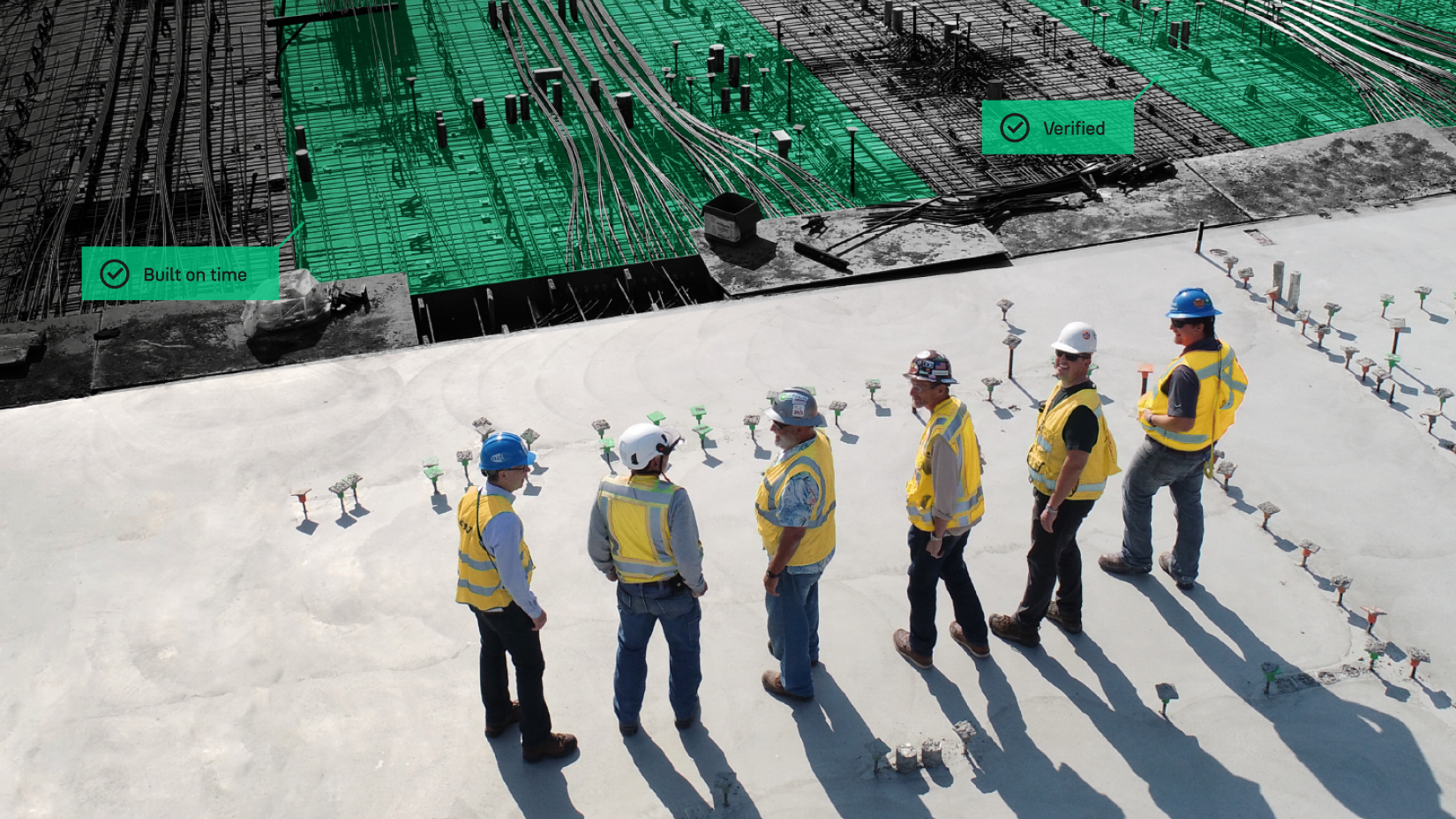

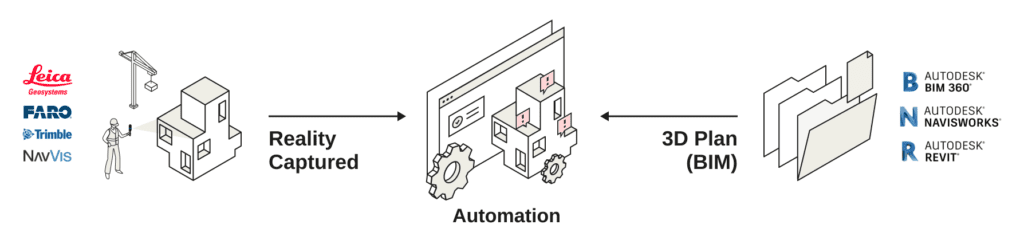

The solution to this problem is to automate quality control to make it possible using AI.

So how do we solve this problem? We believe better information at the right time to make better decisions can redefine how projects are delivered. Leveraging the power of AI to automate the validation of 100% of what is built. Continuously comparing the 3D plan (BIM) with what is being built, flagging deviations from the plan early and alerting the project team to take corrective action before problems become more significant. Radically reducing risk, costly errors, rework, and project delays, leading to significant cost savings and better outcomes for construction projects.

Conclusion

The challenges faced by project teams will continue to increase, with the pressure of increasing material prices, skilled labour shortages and the sheer scale and complexity of construction projects. It is no longer impractical or cost-prohibitive to validate 100% of a project and deliver back actionable information to stakeholders to de-risk project delivery.

AI-powered construction tools offer up the opportunity to radically change the way we deliver projects, delivering a new perspective to inform decisions, and keeping projects running smoothly. Reducing risk and securing profit margins.

Source: Medium.com